|

|

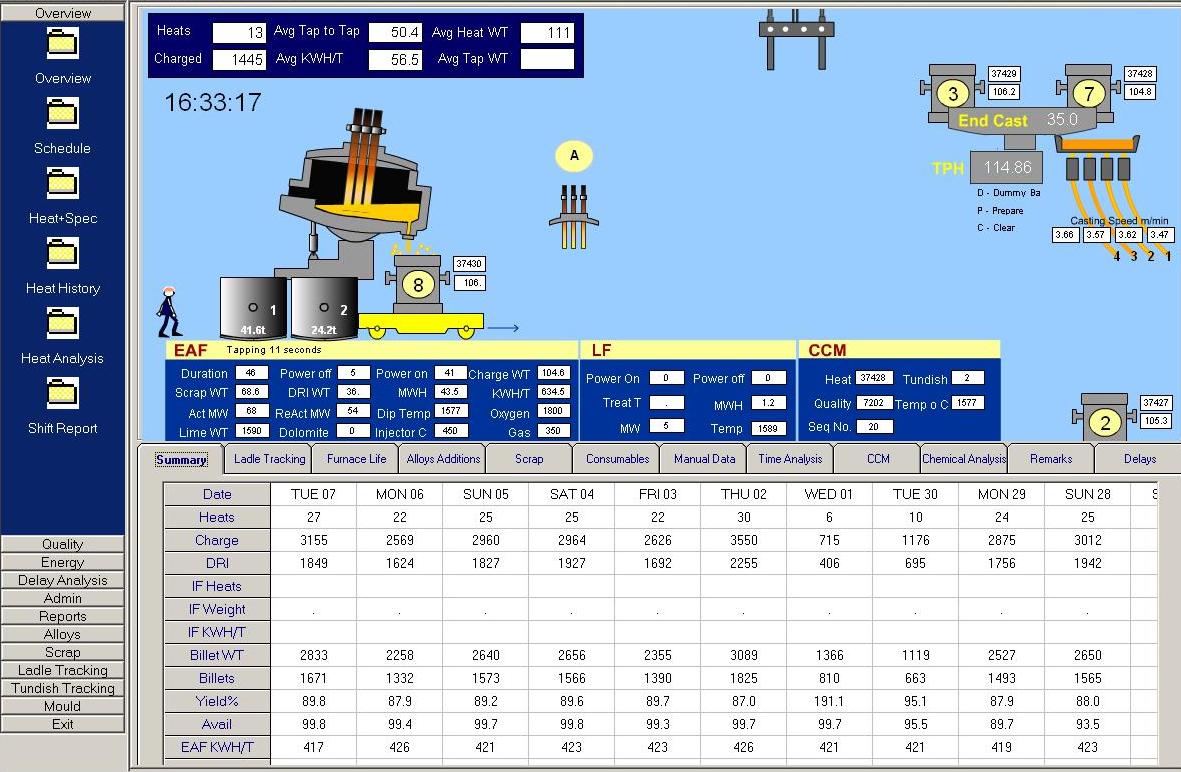

STEEL PLANT PROCESS TRACKING AND MONITORING

HEAT TRACKING

The software module communicates with the plant PLCs seamlessly via OPC interface to track the heat from the scrap basket loading to the caster. The real time process data are recorded against each heat. These data are displayed at each control room to assist the coordination of the shop production. The data include

- Heat status on Basket loading, EAF, LF and CCM

- Real time chemical analysis sample

- Alloy additions

Electricity, gas, oil and oxygen consumptions

- Operation Time and down time is recorded in second automatically

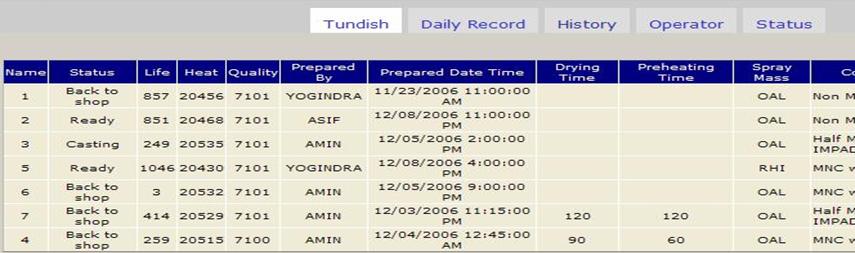

- Life tracking for Furnace, Electrode, Ladle, Tundish and mould

|

|

|