|

Production Planning

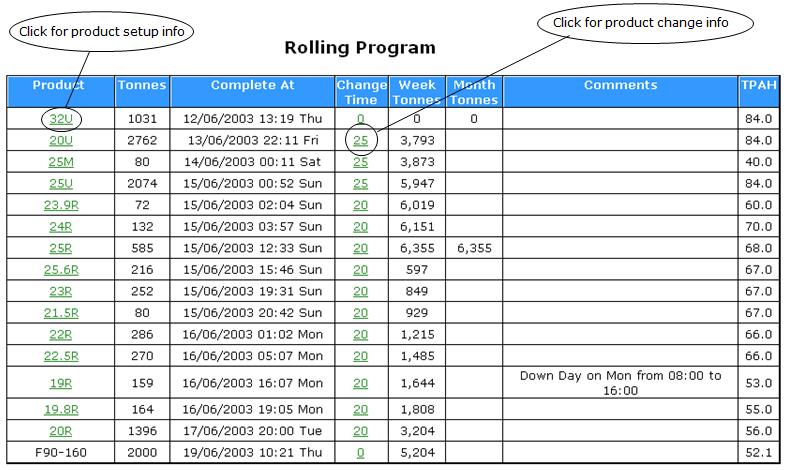

Production Planning is also called Rolling Program. It is an application that groups all the customer orders and planned working orders into a production rolling schedule. It is high level production planning. The orders and tonnages are grouped to the product dimension and section. It also provides the utility to calculate the average rolling speed (TPAH) from last 3 rolling campaigns, define size change time and planned maintenance or shutdown time. The program can predict the size change and rolling output for a longer period such as a month.

Rolling Program is integrated with the Mill Tracking so it is updated automatically. Each department in the rolling mill plans their work according to the program. This includes the product setup, stand build up, shear blade, loopers and troughs and roll turning jobs.

The rolling time prediction of the product is also used by the Meltshop plant, the commercial and the transport department in order to coordinate their work.

|