Automated and Paperless Delay Booking

The system supports many delay definition algorithms that meet the requirements from many different processes such steel making, iron making, DRI process, single line or multiple lines of rolling mill, casting process etc..

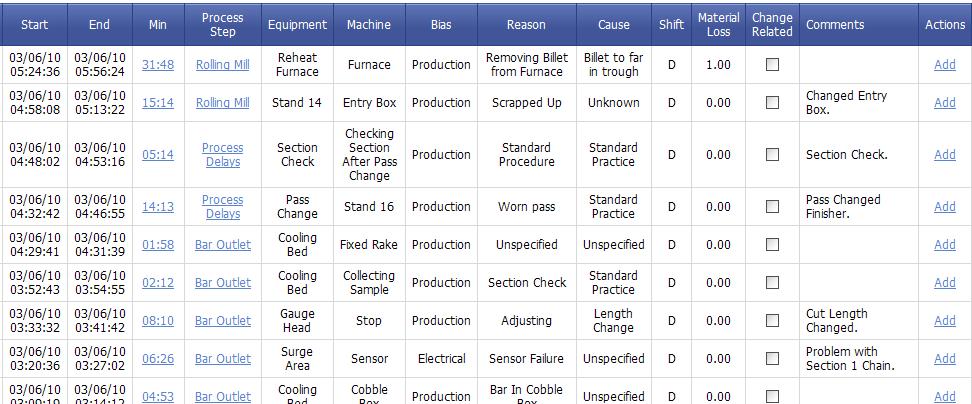

The delay is booked automatically in the accuracy of second. In most cases, the system will monitor the process via the PLC information. When a delay event is triggered, the system will automatically create a delay record with the default category. Once the system detects the start of the process, it will complete the delay with the exact end time. This automated process will not only achieve the time accuracy but also release the operator from the manual data entry task.

Since the delay has been taken care of by the system, operator can then concentrate to provide the accurate reason for the delay. The delay booking has been made very easy. Operator can do it just by a few mouse clicks. This completely removes the need of any paper. In summary, the system will

- Create the delay record automatically

- Operator can specify the delay reason and cause by a few mouse clicks

- Operator can split a delay into multiple delays

- Operator can add more detailed information or comments

- Delay data will be available instantly

- Real time process utilisation (availability) will be calculated based on the delay data

- Achieve paperless delay booking

- Action to prevent or reduce the furture occurance of the same time delay can be created and its progress can also be monitored

- Delay summary is automatically imported into the shift or daily production report

|